Benefits of Electric High Tensile Fencing

Electric fencing is usually considered a “temporary” fencing solution; not a permanent fencing solution like barbed wire or woven wire fences. Tell your customers that nothing could be farther from the truth.

Electrified high tensile fencing is a permanent fencing solution. In fact, it is a better choice when compared to barbed wire, woven wire and other permanent, non-electrified barrier fences.

Why Electrified High Tensile Fencing is Better

Electrified high tensile fencing is the best way to contain or keep out animals. It’s economical, easy to install and maintain and offers better control than conventional barrier fences, such as barbed wire and woven wire fences. It’s also less harmful than barrier fences, which routinely cut, gouge and scrape livestock, leading to expensive vet bills and production losses.

1. Costs Less

Iowa State University explained that a permanent 5-strand high-tensile electric fence will cost approximately 43% less per foot than a 5-strand barbed wire fence and 53% less per foot than a combination single strand of barbed wire on top of a 48” woven wire fence.

2. Looks Great and Stays that Way When Well-Built and Maintained

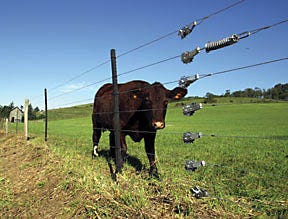

Barbed wire and woven wire fences almost immediately begin to sag and wear due to animal pressure; the act of animals using the fence as a “back scratcher”. Electrified high tensile fences, shock the animal upon contact. This electric shock keeps the animal off the fence; electrified high tensile fences are not susceptible to animal pressure.

3. Electric High-Tensile Fencing Lasts Longer

- An electrified, high-tensile fence can last 25-40 years

- A low carbon, barbed wire or woven wire fence will last 7-12 years

The class lll galvanization used on a 12-1/2 gauge, high carbon, high tensile fence wire inhibits rust from forming for years and years.

4. Easier and Faster to Install

Rolls of barbed wire and woven wire are heavy and cumbersome; just loading and unloading these rolls of fencing onto a work truck requires back-breaking labor. Unrolling these rolls of fence down the fence line as your customer fixes them to the fence posts is very hard work. Tightening/stretching these fences to get the sag or slack out of them is a laborious, time-consuming process.

Electrified, high tensile fences are much less cumbersome and laborious to install. The smooth, 12-1/2 gauge fence wire doesn’t snag and cut like barbed wire and woven wire when you handle it during installation. Simple fence tools like a de-reeler/spinning jenny make the work much easier.

5. Easier to Stock in Your Store

The sheer bulk and weight of barbed wire and woven wire uses a lot of space in your store and warehouse. High-tensile wire and its related supplies will only use a fraction of that space and are much easier to display thanks to the attractive packaging provided by Zareba®.

When it’s time to for your customers to build a new, permanent fence or replace an existing barbed wire or woven wire fence, suggest to them that they rethink the whole concept. Tell them that building an electrified, high tensile fence is the way to go …you’ll be glad you did.